-

tel:

+86 18168939059 -

email:

sunny@wafullwater.com

Fine Bubble Tube Diffuser

The aeration bubble air tube diffuser is a new type of aeration facility. Also known as compressed air aeration.

The principle is to use a blower to transport air through a gas pipeline to the aeration device at the bottom of the pool, disperse and escape in the form of bubbles, and dissolve oxygen into the water at the gas-liquid interface. The microporous tube aerator is made of imported EPDM rubber, the air pipe is made of engineering plastic ABS, the diameter of the bubbles diffused by the rubber diaphragm is small, the air-liquid interface area is large, and there are a large number of self-closing holes. With oxygenation and stopping operation, the holes can be opened and closed automatically. Therefore, no defects such as clogged holes and stains will occur.

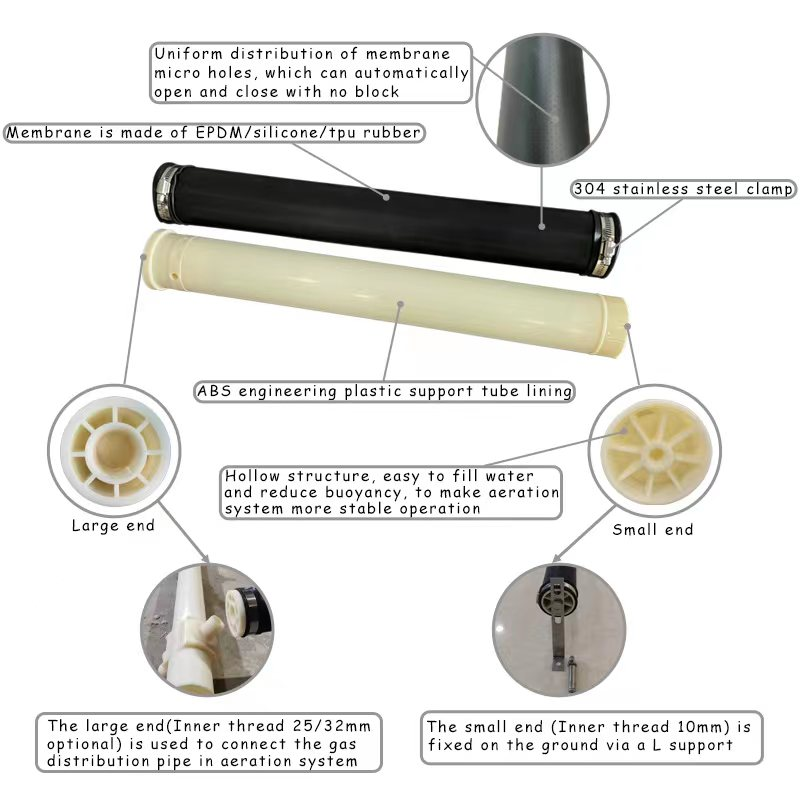

As above picture shown, one bubble air tube diffuser is composed of ABS engineering plastic tube support, two 304 stainless steel clamp, EPDM/Silicone/tpu membrane,one large end and one small end.

The support tube of the aeration tube is made of high quality ABS material. The aeration membrane orifice membrane is sleeved on the support tube, and both ends are locked and fixed with stainless steel clamps. It adopts the air supply main pipe and the air guide groove to pass the silicon rubber membrane or the EPDM membrane to open the holes for micro porous aeration. During aeration, the air first enters the air distribution main pipe through the fan, then enters the air distribution branch pipe, and finally enters the aeration pipe air duct. An annular air chamber is formed between the aeration membrane and the support tube, so that the aeration membrane bulges and passes through the membrane. The stretchable micro pores on the film aerate to the water body. When the air supply is stopped, the diaphragm resumes contraction and continues to close to the support tube, and the micro pores are also contracted and closed, preventing the water body from flowing back into the gas tank.

Comparison between EPDM/Silicon:

1. Price: The raw material cost of EPDM is lower than that of Silicon membrane.

2. Temperature: Silicone rubber has better temperature resistance. EPDM rubber has a temperature resistance of 150 °C, and silicone rubber has a temperature resistance of 200 °C;

3. Weather resistance: EPDM rubber has better weather resistance, and the rubber itself is environmentally friendly, also in a humid environment, EPDM rubber is less likely to breed bacteria;

4. Tear and puncture resistance: EPDM rubber is better.

5. Other: EPDM rubber has good ozone resistance and high strength; high hardness, but poor low temperature brittleness; while silicon has good elasticity and low temperature resistance; but the ozone resistance is general and the strength is low.

Suggestion:

EPDM rubber membrane

Applicable to municipal sewage, animal slaughter processing, food processing, beverage production, industrial waste water.

Silicone membrane: suitable for waste water from pulp and paper industry, petrochemical and refining processing.

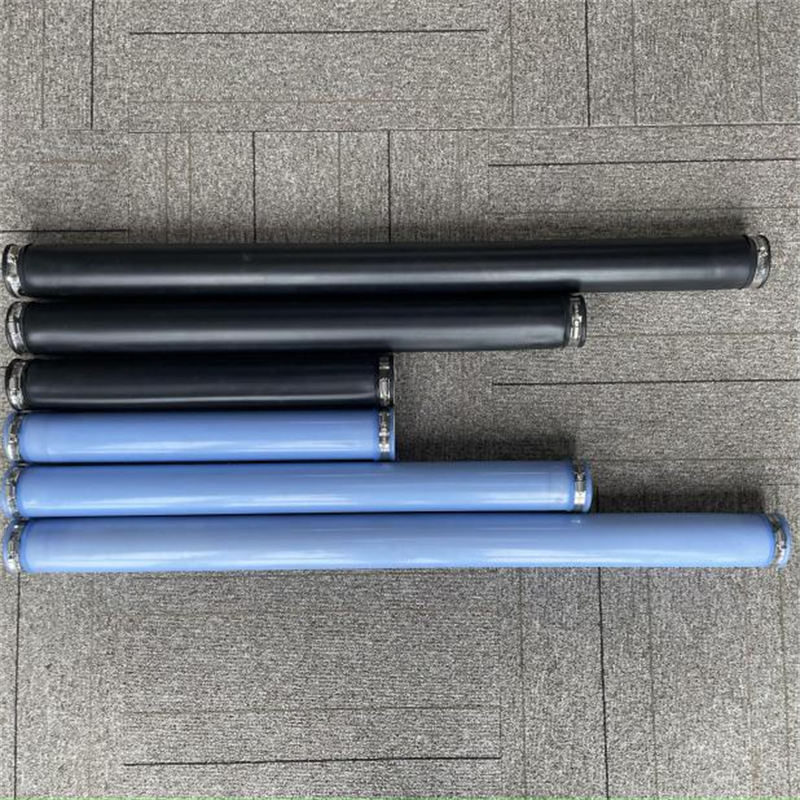

Tube diffuser Size

63*500mm,63*750mm,63*1000mm,

90*1000mm,110*1000mm or customized length.

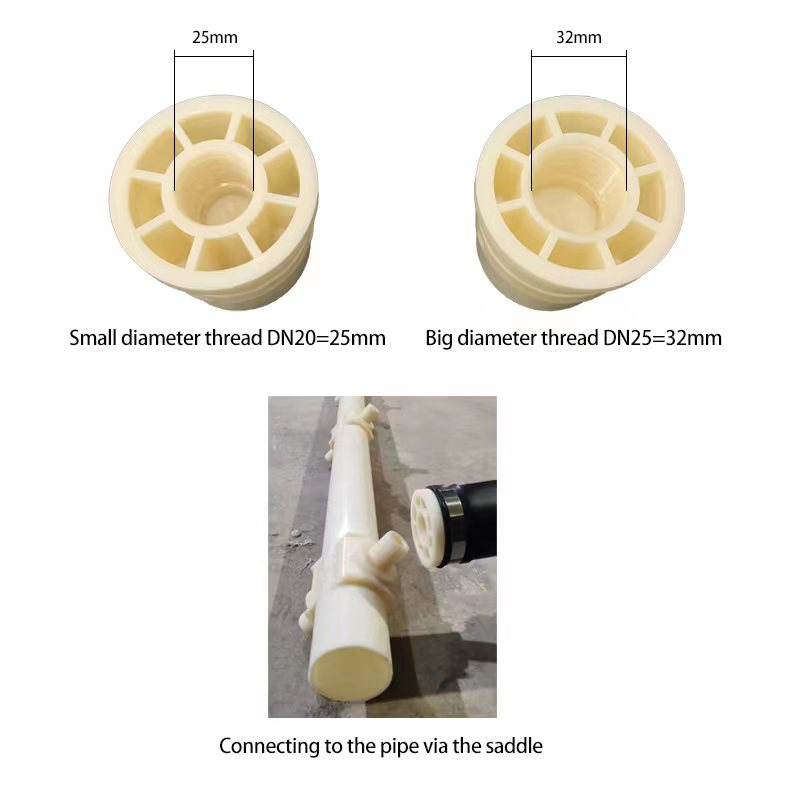

Thread Size Diameter

1. Aeration of fishpond and other applications

2. Aeration of deep aeration basin

3. Aeration for excreta and animal waste water treatment plant

4. Aeration for denitrification/dephosphorization aerobic processes

5. Aeration for high concentration waste water aeration basin, and aeration for regulating pond of waste water treatment plant

6. Aeration for SBR,MBBR reaction basin, contact oxidation pond; activated sludge aeration basin in sewage disposal plant

|

Parameter |

Unit |

Specification |

||||

|

Effective diameter*Length |

mm |

63*500 |

63*750 |

63*1000 |

90*1000 |

110*1000 |

|

Service Area |

㎡ |

0.3-1 |

0.4-1.5 |

0.5-2 |

0.75-2.5 |

1-3 |

|

Standard ventilation |

m3/h (Standard status) |

3-4 |

4.5-6 |

6-8 |

9-12 |

15-17 |

|

Standard oxygen mass transfer rate SOTR (oxygenation capacity) |

Kg/h |

≥0.52 |

≥0.535 |

≥0.55 |

≥0.58 |

≥0.62 |

|

Standard oxygen mass transfer efficiency SOTE (oxygen utilization rate) |

% |

≥31 |

≥32 |

≥33 |

≥35 |

≥38 |

|

Standard aeration efficiency |

Kg/(kW*h) |

≥7.9 |

8.1 |

8.4 |

8.9 |

9.5 |

|

Drag loss |

Pa |

≤4500 |

≤4500 |

≤4500 |

≤4500 |

≤4500 |

Bubble air tube diffuser which is fixed on the floor.

Liftable bubble air tube diffuser system,easy to replace without downtime.

.png?x-oss-process=image/resize)